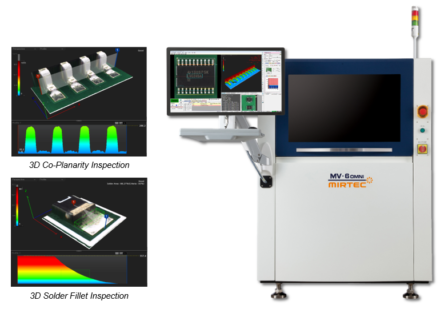

Absolute EMS, Inc., a leading provider of turnkey and consignment manufacturing services, is pleased to announce that it has installed two new MIRTEC machines at their facility: an MV-6 OMNI 3D AOI Machine, and an MS-11e 3D SPI Machine.

Absolute EMS is a leader in end-to-end electronic manufacturing services solutions that help its customers rapidly introduce innovative new technology by facilitating speed-to-market in their marketplace. Speed-to-market starts with engineering services, and extends into prototypes, pilots and then into production.

“MIRTEC’s reputation proceeds them, offering the highest level of customer service and the most advanced inspection technology available on the market,” commented Doug Dow, COO of Absolute EMS. “We at Absolute EMS are very excited to partner with MIRTEC, having installed two of their award-winning machines in our state-of-the-art manufacturing facility.”

The industry acclaimed MV-6 OMNI 3D AOI Machine combines MIRTEC’s exclusive 15 Mega Pixel CoaXPress Camera Technology with their proprietary OMNI-VISION® 3D Digital Tri-Frequency Moiré Technology to provide precision inspection of SMT devices on finished PCB assemblies. MIRTEC’s exclusive 15 Mega Pixel CoaXPress Camera System is designed and manufactured by MIRTEC for use with its complete product range of inspection equipment. MIRTEC’s proprietary Digital Tri-Frequency Moiré Technology, provides superior 3D inspection of SMT and Thru-Hole devices up to 25mm tall. This award-winning technology yields precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera.