The Application

Smooth rolling and reliable gripping are just a few of the requirements that drivers place on tires. To meet these demands, tire manufacturers process a variety of raw materials and semi-finished products during production. These materials must be tracable at any time – during and after production. This requires identification solutions that make the entire manufacturing history accessible.

The Goal

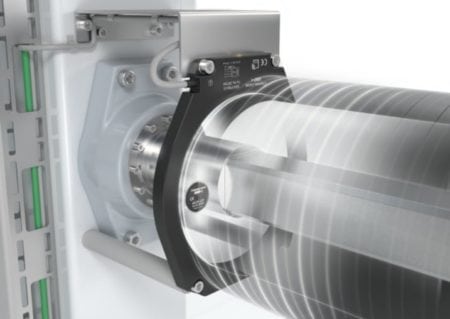

The F198 has an application-specific read/write head for optimal traceability

In the production of vehicle tires, machines are used in pre-production to coat steel threads with a rubber composite and form them into cap strips. These strips are then wound onto a spool and fed into the tire building machine. For identification, an RFID tag is embedded in each spool. However, when loading the cap strip and tire building machines, the tags can be located in varying positions, depending on the rotation of the spool. In addition, the metal spool holder impairs radio communication between the reader and the tag. Despite these challenges, reliable identification must be ensured.

The Solution

Reading and writing can take place while the spool is stationary or rotating

Pepperl+Fuchs’ IQH1-F198-V1 RFID read/write head offers an ideal solution. Its ring-shaped design allows spools to be guided through the read/write head, ensuring that RFID tags are always within the F198’s detection range. This means that employees do not have to pay attention to the position of RFID tags when changing spools. Since the tag is always in range, reading and writing can take place while the spool is stationary or rotating. This ensures reliability and traceability of the semi-finished products at all times. Despite the metal surroundings with densely packed spools, the reader’s functionality is not impaired.

The Benefits

The F198 read/write head operates in the high-frequency range and has a read range of up to 15 cm. The ring-shaped design allows tag identification at any position within the detection field, for flexible reading and writing in the described application at any time. In addition to the special HF read/write head and robust RFID tags for industrial applications, the complete RFID solution consists of control interfaces for forwarding data to PROFINET, EtherNet/IP, or EtherCAT. The system is rounded off by tailor-made cabling from Pepperl+Fuchs’ broad connectivity portfolio, ensuring seamless integration of RFID components.

At a Glance:

Application-specific read/write head for optimal traceability

Reliable, material-independent detection via HF RFID technology – even with metal surroundings

Position-independent tag reading and writing, even during rotation

Complete RFID system solution from a single source for seamless integration