Unlock the world of perfect PCB interconnections with TE Connectivity’s Micro-Match connectors! Compact yet powerful, these connectors outshine typical IDCs, offering smaller size, stable connections, and optimal properties. Dive into the details – explore the game-changing world of TE Connectivity’s micro-match connectors.

FRANTIŠEK ĎURÍŠEK SOS electronic Product Specialist More articles from the author

Micro-match connectors by TE Connectivity

It is a series of connectors used to connect printed circuit boards (PCB) to each other in three possible ways.

3 options for using micro-match connectors:

- as BTB (board-to-board) connectors

- as WTB (wire-to-board) connectors, where the individual wires of the connector are crimped onto corresponding wires

- as IDC connectors (insulation-displacement contact)

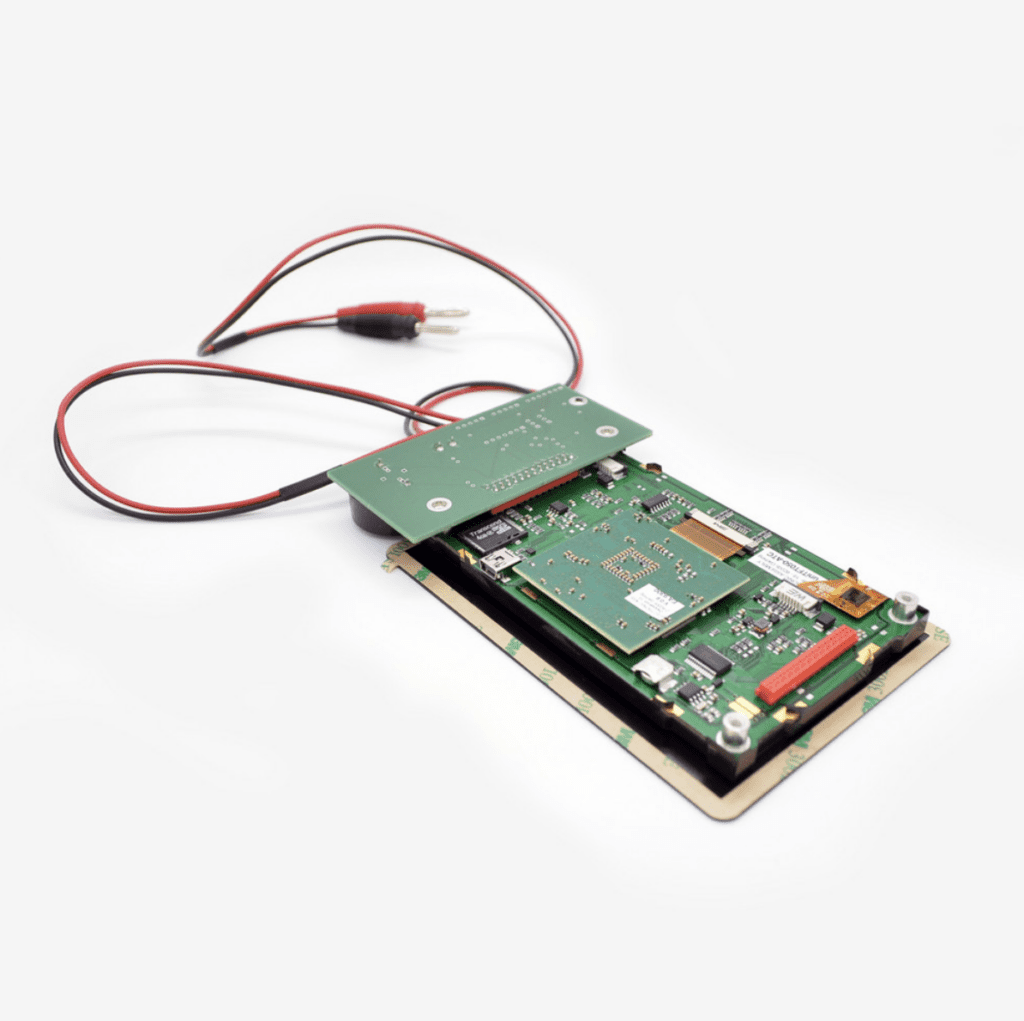

Of these three options, the most common method for connecting two PCBs using micro-match connectors is through IDC connection for ribbon cable with a distance between individual conductors of 1.27 mm, a conductor cross-section of AWG28 (0.08 mm2 to 0.09 mm2) and the outer diameter of the conductor insulation of 0.9 mm. We have chosen this ribbon cable from our range as an example: AWG 28-10 G.

What is the difference between IDC technology and crimping?

The technology of connectors‘ contacting, known as IDC (Insulation-Displacement Contact), sometimes also referred to as IPC (Insulation-Piercing Contact), is a process where a conductive connection between the connector contact itself and the conductor of the flat cable is created by pushing the connector contact blades through the insulation of the flat cable wire.

For history enthusiasts, it’s worth noting that this technology originated in the 1950s, and its pioneers were the Western Electric Company and Bell Telephone Laboratories.

On the other hand, crimping technology is a process where each individual wire (with a precisely defined part of the wire stripped of insulation) and the connector contact are inserted into a crimping machine or crimping pliers, and the conductive connection is then formed by crimping. Subsequently, such a crimped wire with the contact is inserted into the connector housing.

Both types of connections, assuming they are correctly implemented, have high reliability and a long service life.

An interesting point worth mentioning is that all products from the micro-match series of TE Connectivity connectors have tin-plated contacts since their design doesn’t allow for gold-plated contacts.

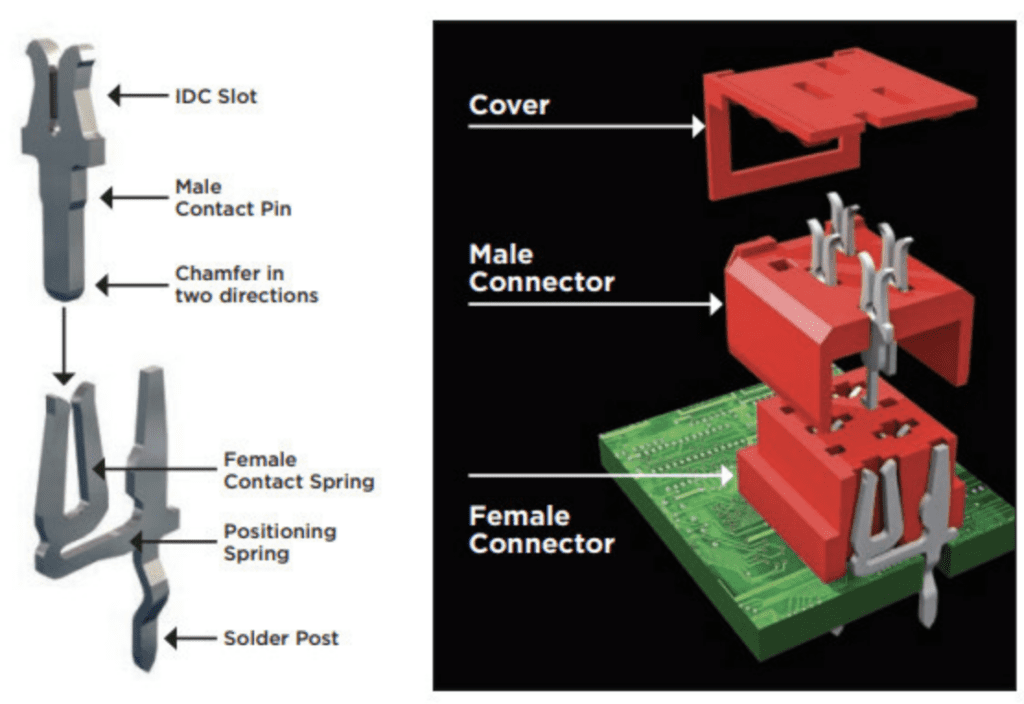

Design of the contact and design of the micro-match connector by TE Connectivity:

“As with any IDC connector, the flat cable connects to these micro-match connectors very easily, as opposed to the lengthy crimping of individual wires. It creates a fast and reliable connection of individual printed circuit boards, thanks to their smaller dimensions they are easy to work with, and versions with locking do not fall out of connection even in a vibrating environment,” says František Ďuríšek, product manager at SOS electronic, based on his practical experience.

Basic categorization of TE Connectivity micro-match connectors

Based on the temperature range, we differentiate between:

- the main types from the micro-match series with a temperature range of –40 – +105°C, which are red in colour, or

- value-line series with a temperature range of -30 – +85°C, distinguished by a black colour.

By connection type:

For the PCB:

- THT

- SMT

- THT Press-Fit

For the cable:

- IDC

- with individual crimping pins (COSI <crimp-on-snap-in> connector)

Main advantages of micro-match connectors by TE Connectivity:

- Compact dimensions, smaller than the well-known IDC connectors with a pin pitch of 2.54 mm.

- Variable pin counts from 4 to 24.

- Versions wire-to-board and board-to-board

- SMD connector soldering possible via reflow or infrared processes.

- Temperature range –40 – +105°C

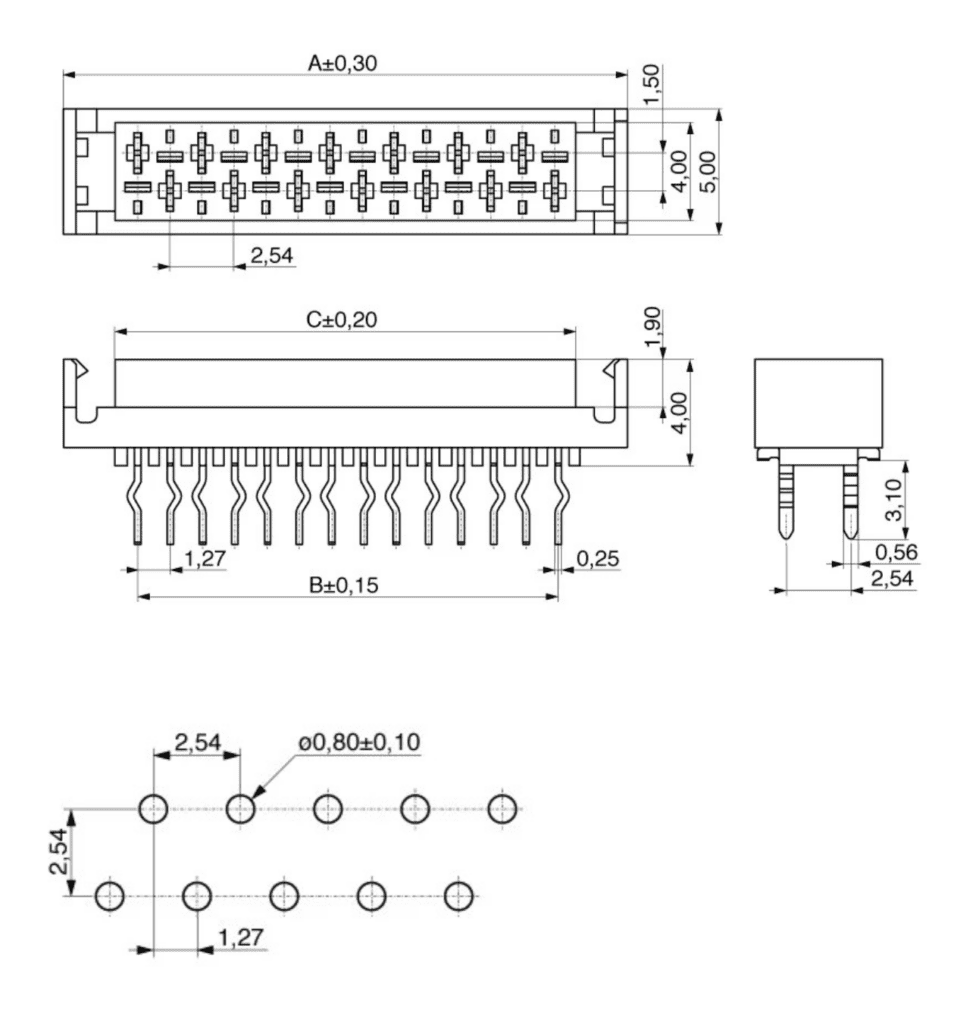

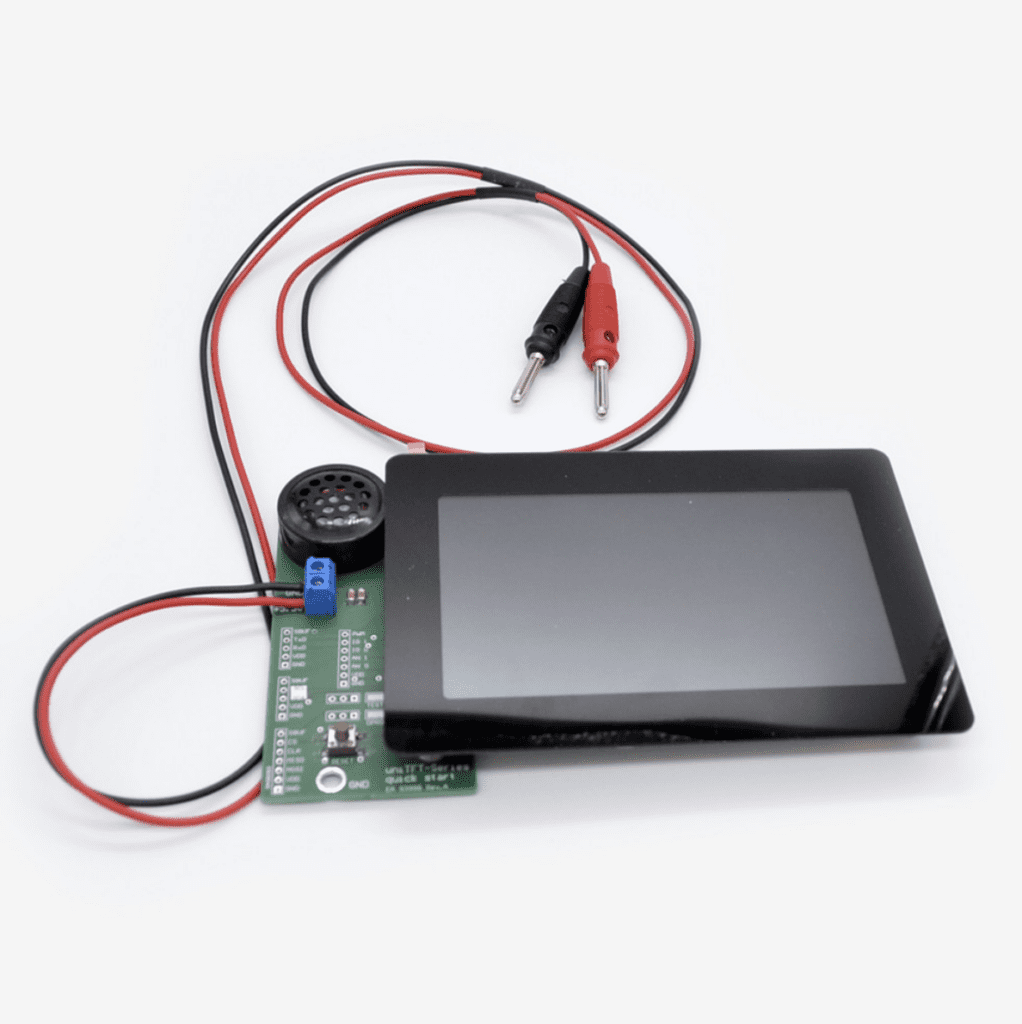

The following image shows a connector version with position locking to prevent accidental disengagement or connector fallout, for instance due to vibrations. In the table below, you can observe the differences in dimensions.

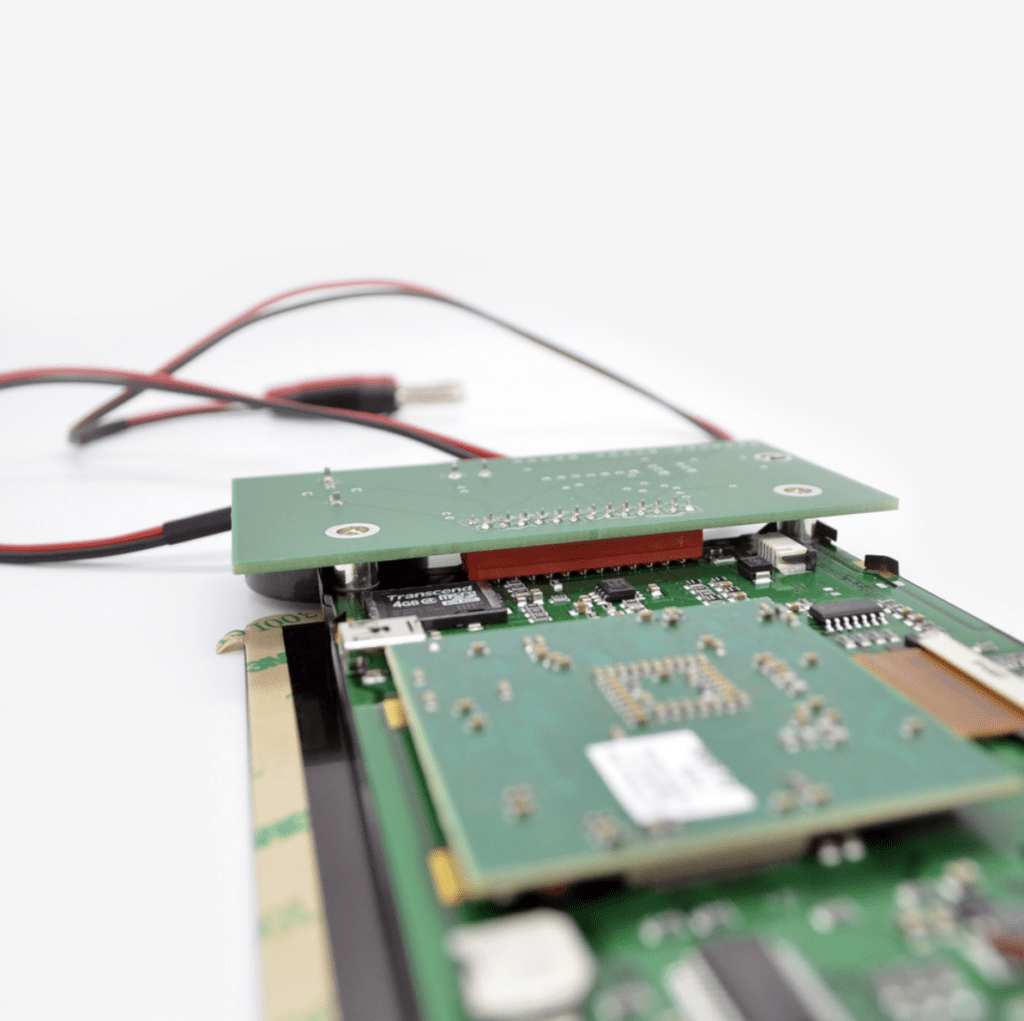

Micro-match connectors are smaller than commonly known IDC connectors. The most interesting parameter is the height, which offers broader options for stacking multiple PCBs on top of each other.

For example, with the most commonly used combination of a socket bar (8.5 mm) and a pin bar (2.8 mm), the stacking height for a spacer pillar is 12 mm. Thanks to its height, the micro-match connector fits securely even with the cable.

Comparison of dimensions of micro-match and standard IDC connectors

For comparison, we selected TE Connectivity’s micro-match connectors 1-338069-0 and 1-215083-0 and standard IDC connectors 2 x 5 pins from Harting 09 18 510 7324 and 09 18 510 7803.

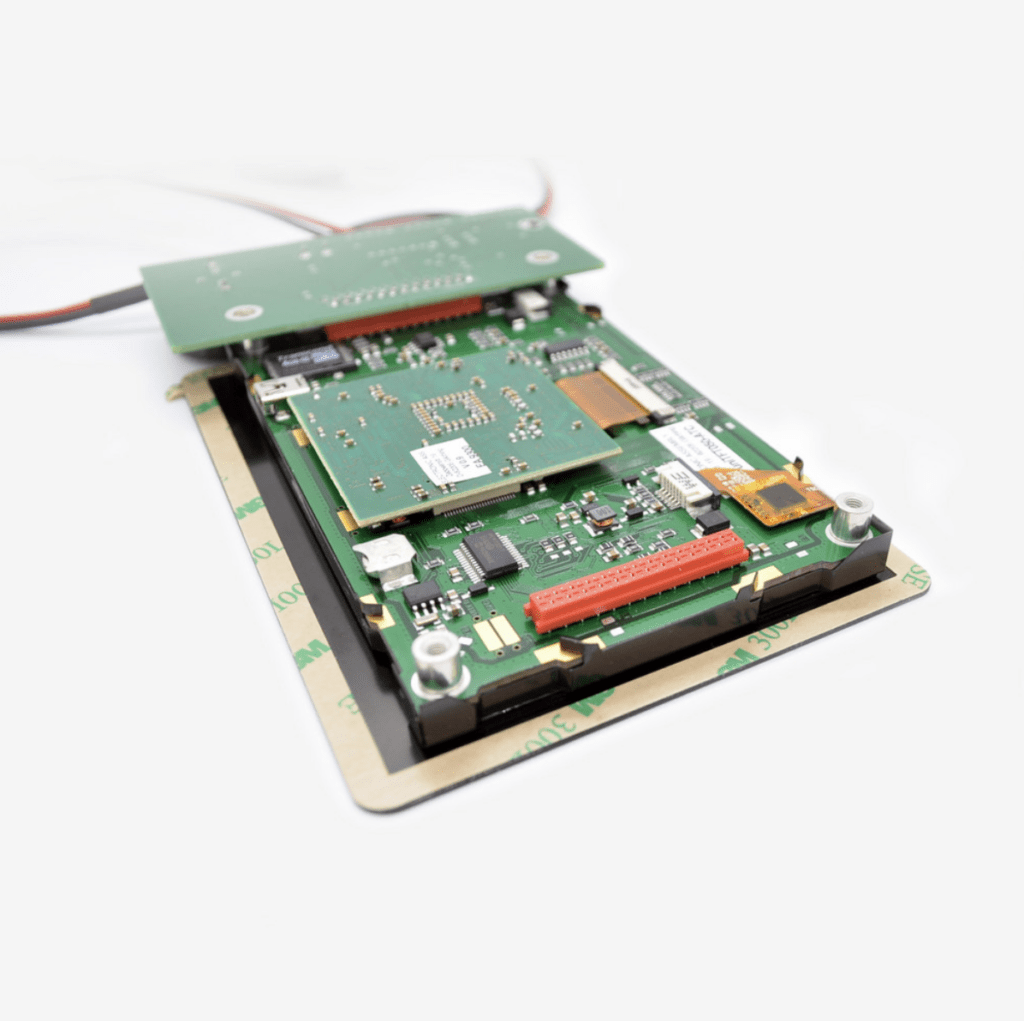

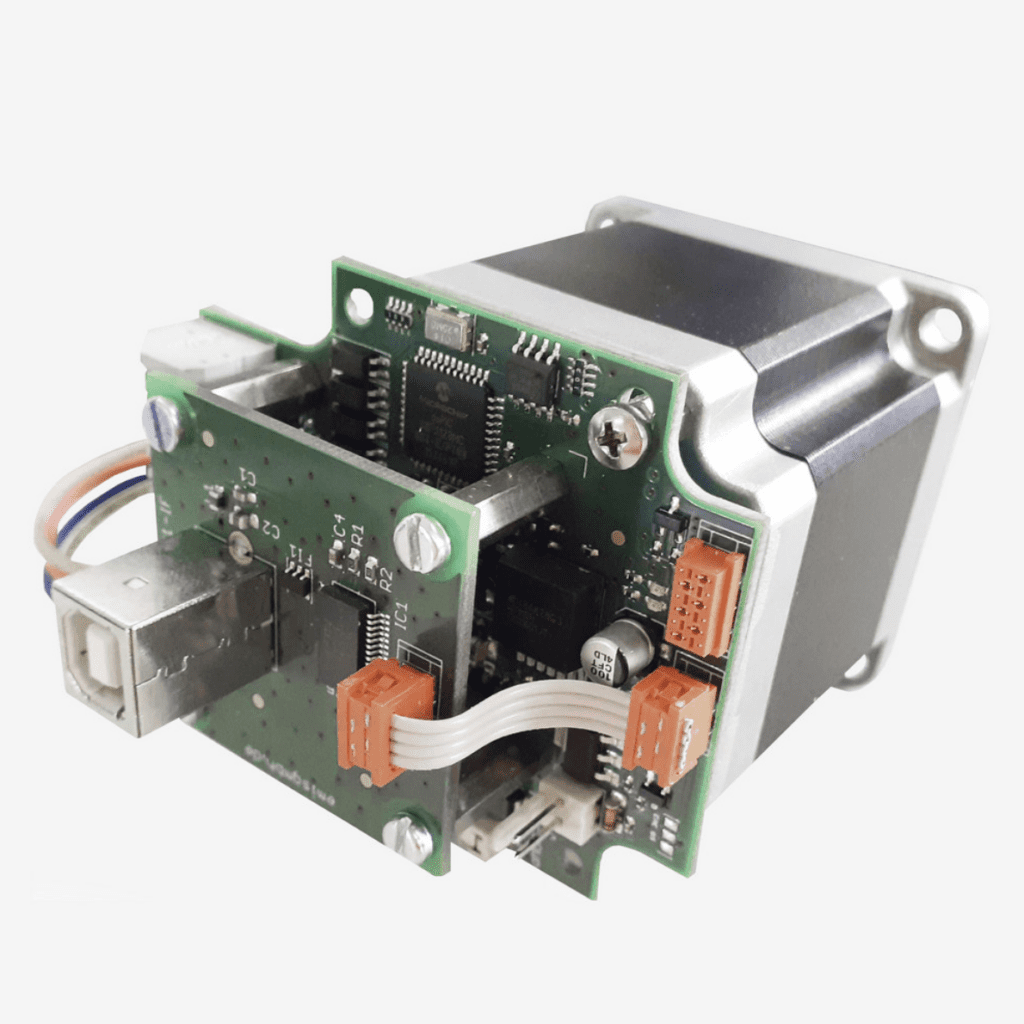

“Micro-match connectors are my favorite. I stumbled upon them by chance fifteen years ago, actually recommended by an older colleague, a developer. Since then, I’ve been using them very often, especially in devices with electrical drive, where I interconnected individual PCBs. For example, a control unit with a position sensor module (2×3 pins), another one with a temperature module (2×2 pins), or a display module. In serial production, the individual connectors were not interchanged during assembly, because I used connectors with different numbers of pins. As the number of units in the series increased, it became possible to replace the combination of connectors to the PCBs + IDC connector with just one IDC connector for the PCB,” concluded František Ďuríšek.

Everything you should know about micro-match connectors by TE Connectivity

If you are not yet familiar with micro-match connectors, read a practical and comprehensive summary directly from the manufacturer of these connectors, TE Connectivity.

You can find all the important information regarding the basic line of micro-match connectors in this article, and if you are interested in the black value-line series, read this article directly from the manufacturer.

SOS electronic stock the most commonly used types of TE Connectivity micro-match connectors.

Are you interested in more information on TE Connectivity products or technical advice when choosing a product? Or do you have another question or request? Do not hesitate to contact SOS electronic.

Try a sample for your project

Do you need to test a component during development? Feel free to contact SOS electronic and ask to provide you with a sample for the project. We assess each request individually, so please provide a brief introduction of your project in the following form.

They only provide samples for projects in development, not for private use by individuals.

Thank you for your understanding.