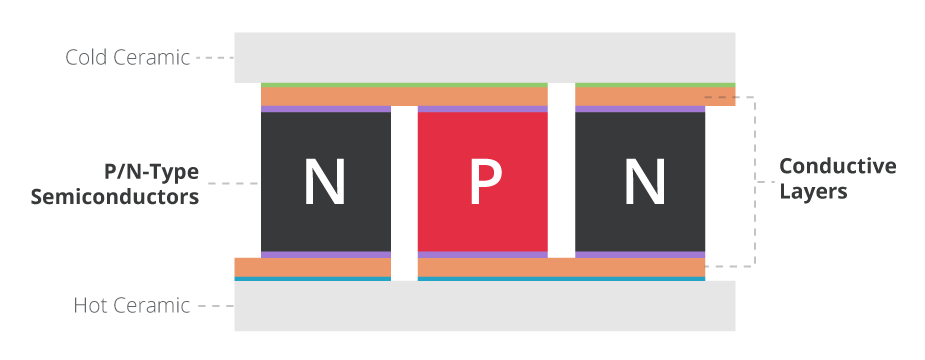

Peltier Module Construction

Peltier modules are solid state devices which contain no moving parts and operate within a wide range of temperatures. The construction of Peltier modules has been addressed in this CUI Devices whitepaper, but here is a quick refresher to aid in the discussion.

The construction of Peltier modules consists of positive and negative doped pellets of semiconductor material placed between two electrically insulating but thermally conductive plates of ceramic. Conductive patterns of metal are plated on the inner surfaces of each of the ceramic plates and the semiconductor pellets are soldered to the conductive patterns. This module configuration places all of the semiconductor pellets electrically in series and mechanically in parallel. The series electrical connections enable the desired thermal effects and the parallel mechanical configuration causes heat to be absorbed by one of the ceramic plates (the cold side) and released by the other ceramic plate (the hot side).

Peltier Module Failure Mechanisms

The most common failure mechanism of Peltier modules is mechanical fracturing of the semiconductor pellets or the associated solder joints. These fractures initially do not propagate completely through the pellet or solder joint and can be detected by a rise in the series resistance of the device. This rise in the Peltier module’s resistance causes a reduction in its overall “efficiency,” but a complete failure can occur if a fracture propagates completely across a semiconductor pellet or solder joint.

Mechanical Tension or Shear

Typical Peltier module applications involve placing an object to be cooled on the cold plate of the module and a heat sink on the hot side. Mechanical failures are likely to occur if the heat sink and the object to be cooled are adhered to the ceramic plates without any other mechanical structure to support the cooled object and heat sink. Using only the Peltier device to support the object or heat sink may cause large shear or tension loads across the module. Peltier modules are not able to withstand large tension or shear forces between the heat sink and the cold plate and may break if such forces are applied.