Drive System Design (DSD) will present two technical papers addressing the challenges faced in the optimisation of electric vehicle (EV) powertrains at the 17th CTI Symposium in Berlin from 3-6 December. Both exhibit a systems engineering approach developed by DSD to optimise the complete powertrain and its cost. The first demonstrates the benefits of using the approach to identify opportunities for lowering the initial investment cost associated with battery technology in the commercial vehicle market. The second describes the process DSD has developed to improve the optimisation of EV powertrains, using an autonomous vehicle application as an example, which introduces unique drive cycle conditions.

Dr Samuel Fraser, Senior Engineer, Control Systems, DSD will present ‘Commercial EVs: applying a systems engineering approach to optimise the powertrain to tackle the total cost of ownership challenge’. The paper documents the optimisation techniques, processes and tools DSD has developed to quantify the impact of the sub-systems on overall powertrain performance, providing insight into complex sub-system interactions and enable appropriate design decisions. Over 4,000 different powertrain permutations were evaluated to find the optimal configuration.

Total Cost of Ownership (TCO) is heavily influenced by vehicle depreciation, which can be mitigated by reducing the initial purchase cost. The analysis showed that, for this application, increasing the motor cost led to lower overall powertrain cost as improved efficiency and reduced energy consumption (battery kWh over a given range) enabled a significant reduction in battery capacity. Further powertrain cost savings were possible by downsizing the motor from 400Nm to 300Nm, using a multi-speed transmission to deliver the necessary wheel torque to meet performance targets. A further benefit of this optimisation approach is a weight reduction associated with the reduced battery requirement, enhancing commercial vehicle payload potential.

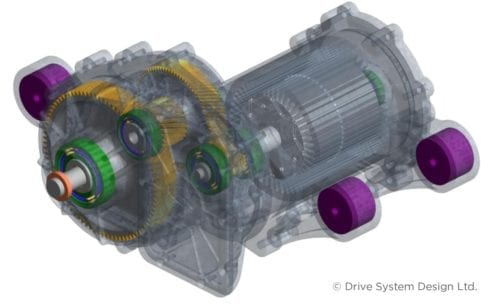

Dr Thomas Holdstock, Control Engineer, will present ‘Electric drivetrain architecture optimisation for autonomous vehicles based on representative cycles’. New technologies for EVs are being continually developed, but the cost of adoption versus the performance benefits are not always easy to compare. This paper describes the processes and tools used by DSD to carry out this evaluation, through a systems approach that thoroughly analyses each possible sub-system to enable concept generation to occur iteratively. Characterisation of sub-system and component level behaviour allows accurate prediction of system performance and cost, enabling mapping of the potential design space, investigation of a wide range of complex interactions, and evaluation of new concepts at a system level.

By eliminating the human driver, an autonomous vehicle subjects its powertrain to a narrower range of operating conditions; the appeal of ‘performance feel’ is replaced by the need to maximise occupant comfort, with a smoother velocity profile and fewer torque peaks, and the need for likely extended total mileage in the duty cycle. This combination of factors permits the selection of a smaller motor and a lighter, lower cost drivetrain, but only if recognised and quantified during target-setting. This approach will ensure that the drivetrain package can be minimised, maximising the occupant volume of the autonomous vehicle.

In addition to the technical papers, DSD engineers will be available throughout the Symposium on stand K08 in Europe Hall to discuss a wide range of topics, particularly control system development, powertrain electrification and eMotor design capabilities. Further details of the DSD presentations, including timings and session details are available on the Symposium website:

http://drivetrain-symposium.world/de/symposium/programme-2018/

About DSD

Drive System Design (DSD) is an award winning engineering consultancy specialising in the engineering, development, test and control of electrified and conventional driveline systems.

The company’s staff have experience working with vehicle manufacturers and Tier 1s around the world, designing new technologies and solving problems to make their products more competitive. They have the engineering, test, analysis and project management skills necessary to deliver projects to demanding timescales. Working closely with its customers through technical centres in Europe and North America, DSD is recognised as a world leading expert in driveline refinement, efficiency improvement and hybrid and electric vehicle transmissions. DSD is ISO 9001 and ISO 14001 certified.