Driving down cost and size are key concerns for OEM design teams everywhere. By focusing only on the Bill of Materials (BOM), it may appear that costs can be saved by designing items like power supplies in-house. After all, a ready-made solution can cost several dollars more. If the end product is to be made in high volumes, the case can seem persuasive.

On the other hand, making a power supply as small as possible is not easy. It can demand knowledge outside the in-house team’s main competencies and may require more expensive PCB assemblies not required by the rest of the product (eg. additional layers and heavier copper).

Other aspects of bringing up the design in-house and supporting it independently can be even more complicated and expensive. Special equipment may be needed, such as high-quality electronic loads for testing. The design team must also ensure compliance with safety specifications such as IEC 60950-1 and any market-specific specifications such as IEC 60601-1 for medical equipment. The Power Sources Manufacturers Association (PSMA), of which CUI is a member, has published the Safety & Compliance Database to help with this, and CUI has published a downloadable guide to applicable safety standards, agencies and marks. The efficiency of the power supply can also strongly influence whether the product will meet Ecodesign regulations, such as the EU’s minimum requirements for products such as LED lighting, white goods, and set-top boxes. In addition, customers will require reliability information and if a product warranty is offered this should extend to cover the power-supply components.

No Easy Task

If the system requires only a small ac-dc power supply or dc-dc converter to provide just a few watts, it may be built directly onto the system PCB, where it must compete for space with the rest of the system circuitry. Components such as the transformer and electrolytic capacitors are relatively large and bulky, and can be difficult to centralize. If the PCB as a whole is intended to have components populated on one side only, the discrete power solution will tend to spread out and consume valuable PCB real estate.

Of course, getting the PCB layout right affects not only the size of the resulting power supply, but is also critical to minimize the emission of high-frequency switching-noise, ensure proper thermal management, and to comply with applicable safety requirements, such as isolation distances.

To overcome these challenges, a reference design from a chosen power component vendor may promise a quick and dependable solution. Power component vendors are skilled at specifying a generic bill of materials, while laying out recommendations and best design practices to cover basic requirements of a wide range of systems. However, every application is different and the OEM team’s designated power supply designer will probably have to deviate from the reference design to meet performance demands, space constraints, thermal, or EMI requirements specific to their application. This can add time and cost to the project, and the resulting discrete power supply still may not perform as well as expected.

As an example, a new application may only require a two layer PCB with 1 oz copper, but the chosen reference design for the discrete power solution recommends 4 layers of 2 oz copper. The option exists to double the PCB layers and double the copper weight of the entire application board, but this comes at a significant cost to the design. In addition, there is still the burden of time to carefully reproduce the manufacturer’s recommended layout of the power planes and traces for the discrete components.

Benefits of an Off-the-Shelf Design

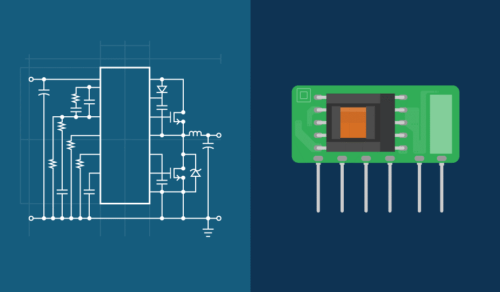

Pre-designed power modules, by contrast, allow engineers to have the best of both worlds; they can design the system PCB using the fewest number of layers and the least amount of copper while leveraging the power module to simplify and optimize the power conversion needs. Instead of spending time evaluating products and reference designs from various discrete component vendors, laying out the power planes, keeping the feedback loop tight and quiet, and making sure no power switches are positioned close to sensitive analog circuitry, engineers can simply choose an appropriately-sized pre-designed power module that has been optimized to minimize board space, allowing them to focus their efforts on other tasks associated with the design.

Unlike a custom in-house power supply, off-the-shelf modules are already tested, qualified, and often pre-certified in accordance with international safety and EMI standards. By selecting a pre-certified power module, the certification process of the end-application can often be expedited. Reliability data is also readily available and, as a warrantied product, the module can reduce the overall cost for the OEM to support its own customers.

An example of a board mount module that is ready to use and can save OEMs development time as well as considerable engineering and support costs is CUI’s PBO-5 series of 5 Watt ac-dc converters. These SIP (Single Inline Package) modules maximize PCB-space savings, are UL and CE certified, and provide safety features including a 3 kVac isolation voltage and short circuit and over current protection.

While there are certainly situations where the low-complexity of the power design coupled with high volume projections can justify a discrete power design, engineers are more often turning to pre-designed power module solutions when performance, reliability, time-to-market, safety, certification, and support are critical considerations. Yes, designing power supplies for your products in-house can trim a few dollars from the BOM, but it can also come at the cost of increased design risk and added development time.

https://www.cui.com/blog/make-or-buy-power-supplies