In-house 3D printing is a versatile solution for a wide range of applications. When you consider investing in a 3D printer, however, viability typically boils down to a simple question: does it make economic sense for your business?

In this guide, we’ll compare outsourcing with in-house production, lay out the various costs you should account for to calculate cost per part, and look at considerations beyond cost when comparing various production methods.

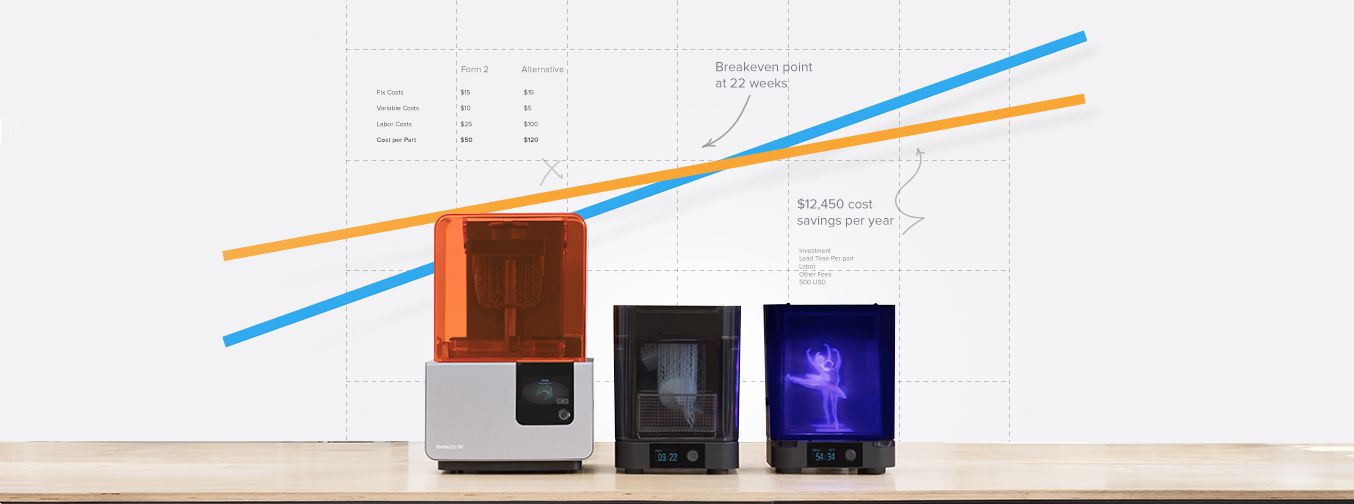

Normally, one of your first steps would be the strenuous task of creating an elaborate spreadsheet and trying to gather all of the—often hidden—information from a manufacturer. To skip this hassle, try our simple, interactive tool to calculate cost per part and lead time when 3D printing on the Form 2, and to compare time and cost savings to other production methods.

Outsourcing vs. In-House Production

Outsourcing production to service bureaus or labs is recommended when you require 3D printing only occasionally, and for parts that are large or call for non-standard materials. Bureaus generally have several technologies in-house such as SLA, SLS, FDM, and metal 3D printers. They can also provide advice on various materials and offer value-added services such as design or advanced finishing.

The main downsides of outsourcing are cost and lead time. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing also rapidly becomes expensive.

Desktop 3D printers are great when you need parts quickly. Depending on the number of parts and printing volume, investment into a desktop 3D printer can break even within months.

With desktop machines, you can pay for just as much capacity as your business needs, and scale production by adding extra units as demand grows without making a significant investment in a large-format 3D printer. By using multiple 3D printers, you also get the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Calculating Cost Per Part

Calculating cost per part requires accounting for the costs of equipment ownership, material, and labor. It’s helpful to understand the factors that influence each of these cost components, and the questions to ask to evaluate alternative production methods and uncover hidden costs.

Equipment Ownership

Fixed costs, such as investment in machinery, service contracts, installation, and maintenance, together make up the equipment ownership cost. These expenses incur regardless of whether a machine stands idle or produces dozens of parts a week.

Distribute equipment ownership costs over individual parts by adding up all of the forecasted fixed costs over the lifetime of the machine and divide the sum by the number of parts that it is expected to produce. As a rule of thumb, the higher the productivity and utilization of the machine, the lower the equipment ownership cost on a per-part basis.

Desktop 3D printers have achieved tremendous progress in recent years in lowering equipment ownership costs. With a price tag 10-100 times lower than industrial 3D printers and the capability to produce thousands of parts over their lifetime, the equipment ownership cost can become negligible.

Questions to ask:

- Are there installation, training, or further initial expenses beside the cost of the machine?

- Is there a (mandatory) service contract? What does it include?

- Beyond the machine, what accessories and tools are required to create final parts?

- What are the maintenance needs of the machine within the normal range of activity? What’s the expected annual cost of maintenance? How does it change if production levels rise?

Materials and Consumables

Raw materials and other consumables required to create parts are variable costs. These costs are highly dependent on the number of parts you’re producing.

Measure material cost by calculating the amount of material that’s required to create a single part, and multiply it by the cost of the material. Calculate in waste and any other consumables that are needed. While equipment ownership costs decrease as the production grows, material costs for 3D printing tend to flatten out quickly.

Make sure to clarify what materials you’ll need to create the given parts, as the cost of consumables for 3D printing varies. Also note that some 3D printers only work with proprietary materials, and thus limit your options.

Questions to ask:

- What is the cost of each type of material?

- How much material is required to create a given part, including waste?

- What’s the shelf life of the materials?

- Are there other consumables required to create the parts?

- Can the machine work with third-party materials?

Labor

While 3D printing can replace the complex workflows of traditional manufacturing methods and lead to substantial time savings, depending on the technology, it can still be a fairly labor-intensive process.

Most desktop 3D printers are optimized for ease of use, whereas regular maintenance or changing materials on industrial machines can involve time-consuming tasks that require a skilled operator.

Post-processing workflows vary by technology, but in most cases include cleaning parts and removing supports or excess material. There are solutions to automate some of these tasks; for example, Formlabs Form Wash and Form Cure simplify the washing and post-curing workflow for stereolithography 3D printing and the Form 2.

Questions to ask:

- What is the entire workflow for producing parts? What are the specific steps required to set up a print, change materials, and post-process parts?

- How much time does it take to post-process a given part?

- Are there any tools or devices available to automate some of these tasks?

Considerations Beyond Direct Costs

Investment, materials, or labor costs are relatively easy to calculate. But what about indirect costs and factors that are hard to quantify, but still influence your business? Let’s look at some of the key considerations when comparing desktop 3D printing to outsourcing or other production methods.

Time savings: What if you could bring products to market months faster? Or cut the lead time for your products by days or weeks? 3D printing simplifies traditional prototyping and production workflows, helping you to save time and outpace the competition.

Better results: 3D printing allows you to create more iterations, fail faster, and achieve better end products. Finding and fixing design flaws early also helps to avoid costly design revisions and tooling changes in production.

Communication: Having high-quality prototypes and parts allows you to better communicate with customers, clients, suppliers, and other stakeholders. Avoid confusion and costly mistakes.

IP protection: Do you work with sensitive information? Creating parts in-house means you won’t have to give away intellectual property (IP) to third parties, reducing the risks of leaks or IP theft.

Calculate Your Cost and Time Savings in Minutes

Calculating cost per part, lead time, and comparing alternatives typically requires working extensively with spreadsheets, but what if it only took a few minutes?

Try our simple, interactive tool to calculate cost per part and lead time when 3D printing on the Form 2, and to compare time and cost savings to alternative production methods using your own metrics.