Valves are integral parts of piping systems for conveying liquids and gases and are available in various sizes and designs. Their sole purpose is the control and regulation of these media in a secure manner.

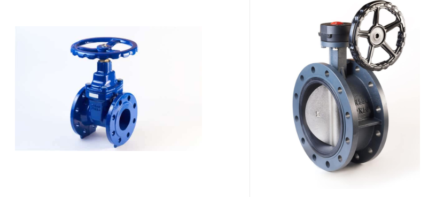

Gate valves and butterfly valves are two of the most popular types of industrial valves. These two have huge differences in both of their structural designs, usage, and working conditions.

In this article, we are going to discuss the differences between gate and butterfly valves. Let us start by defining these two in the next section to find their differences before we elaborate further on the details.

Defining Gate and Butterfly Valves

|

|

What is a Gate Valve?

Gate valves, also known as sluice valves, cut off a medium in a pipeline by lifting a rectangular or round “gate” from the medium’s path. The direction of the gate’s movement is perpendicular to that of the medium’s flow.

Gate valves are cut-off valves which are only used when minimum restrictions and uniform linear flows are desired. They can either be completely open or completely closed which does not allow the adjustment of the medium flow. The medium discharge is normally complete and no residues are left in the pipes.

What is a Butterfly Valve?

Butterfly valves are also known as flap valves. They are composed of a fixed disc on the valve’s stem for closing and opening the valve. This disc rotates around the valve’s stem to regulate the flow of the medium in the pipeline. The direction of the disc’s movement is in place rotation only and requires a 90° rotation to fully open or fully close the valve.

Butterfly valves can either be used for regulating or isolating fluid flows and can control the flow easily. However, they leave residual materials in the pipeline.

Differences Between Gate and Butterfly Valves

After the general definitions of gate and butterfly valves, you may have already noticed the differences between the two. Most especially their design, how they work, and their recommended applications. Let us discuss these further by tackling their differences one by one.

#1 Structural Design

Gate valves use a “gate” or a wedge whilst butterfly valves use a rotating disc to allow or prevent fluid flow. Moreover, gate valves and butterfly valves have different body and disc designs as stated below.

Gate Valve

Body-Bonnet Designs

- Bolted-bonnet gate valve,

- Screwed bonnet gate valve,

- Pressure-seal bonnet, and

- Welded-Bonnet gate valve.

Disc Designs

- Wedge gate valve,

- Double-disc gate valve, and

- Conduit or Parallel slide gate valve.

Butterfly Valve

Body Designs

- Lug type butterfly valve,

- Wafer type butterfly valve,

- Flanged butterfly valve, and

- Butt-welded butterfly valve.

Disc Offset Designs

- Zero offset (concentric) butterfly valve,

- Double offset (double eccentric) butterfly valve, and

- Triple offset (triple eccentric) butterfly valve.

For detailed descriptions of the gate valve types and butterfly valve types discussed above, you can read these two articles.

#2 Working Mechanism

Gate Valve

Gate valves use a movable door or gate to open and close the valve. This gate is lowered or raised using a mechanically assisted operator which is normally a threaded screw. Since gate valves can either be in the fully open or fully closed state, the resistance of the fluid flow when the valve is fully opened is smaller. This is because when the gate valve is fully open, the gate is entirely out of the medium’s path, providing an unobstructed flow.

In general, gate valves act as restrictions to the medium flow and they change the medium’s speed rather than its rate of flow. Moreover, the closing and opening speed of the gate valve is slow due to its high opening height.

Butterfly Valve

Butterfly valves belong to the category of quarter-turn valves and they consist of a rotating disc to regulate the medium flow. The disc is held at the center of the valve’s body by a stem. Unlike gate valves, butterfly valves have a short operation time since the operator is only rotated at 90° to allow or prevent fluid flow in the passageway.

A butterfly valve is usually operated using an actuator which turns the valve’s disc either parallel or perpendicular to the flow. The disc is parallel to the flow when the valve is in the fully open state and is perpendicular to it otherwise. In addition, the butterfly valve’s thickness creates resistance which obstructs the medium flow and causes the pressure to drop even if the valve is fully open.