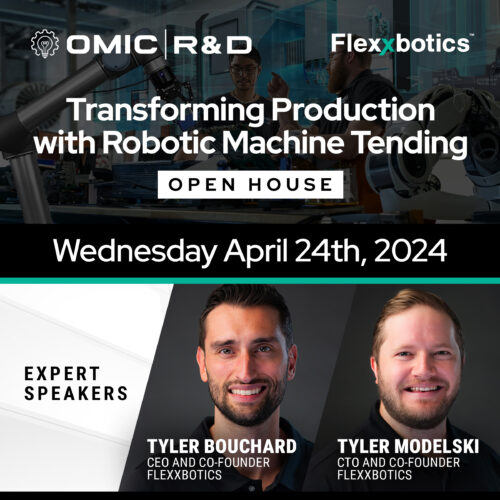

Flexxbotics, delivering workcell digitalization for robot-driven manufacturing, today announced participation in the Transforming Production with Robotic Machine Tending event. The in-person event will be hosted by the Oregon Manufacturing Innovation Center Research & Development (OMIC R&D) on-site at the OMIC R&D factory facility on Wednesday 24 April 2024 from 9am – 12:30pm PDT. Free to Attend | Registration Required

The promise of collaborative robots in advanced manufacturing is significant, and has the potential to fundamentally redefine production operations. Robot-enabling CNC machines provides the ability to run ‘lights out’ safely for additional capacity, precision quality, and improved profit margins.

Recently, OMIC R&D completed its most successful robotic machine tending project to date by using the Flexxbotics solution for robot+machine connectivity and coordination. The half day session will provide an overview of how OMIC R&D cobot-automated CNC production, best practices and innovative options for your own initiative.

OMIC R&D is a collaborative innovation center with a mission to help manufacturers grow, advance, and prosper. It conducts applied research to enhance the ability of industry to manufacture products better, faster, greener, and less expensively. It assists industry in developing new ways to make use of existing technology and pave the way for industry to use new and emerging technologies.

Presentations will include:

- OMIC R&D Advancing Manufacturing for the Future by Urmaze Naterwalla, Head of Research & Development at OMIC R&D

- OMIC R&D Robotic Machine Tending Project for Safety, Quality, and Throughput by Jordan Meader, Robotics Solutions Researcher at OMIC R&D

- Robot+Machine Connectivity, Interoperability and Orchestration by Tyler Bouchard, CEO and Co-founder of Flexxbotics

- Running Advanced Robotic Machine Tending in Production for Continuous Operations by Tyler Modelski, CTO and Co-founder of Flexxbotics

Flexxbotics robotic workcell digitalization is the backbone of the Smart Factory delivering autonomous process control for next generation machining environments utilizing robotics. The SaaS/hybrid solutions are specifically designed to enable robot-driven manufacturing at scale. Flexxbotics breakthrough innovation, the unique FlexxCORE™ technology, seamlessly connects and coordinates robots with existing automation equipment, IT systems and people.

Registration for this free in-person event is required:https://www.eventbrite.com/e/transforming-production-with-robotic-machine-tending-april-24-2024-tickets-868181643667?aff=oddtdtcreator