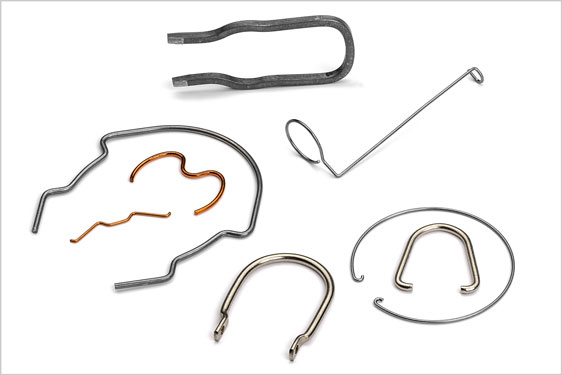

Wire forms typically are parts made from wire that is bent to have specific angles and lengths. They are well known as simple, quick to install and low cost, often as permanent but easily removable devices. These simple wire forms are found in electrical equipment, vehicles of all types, machines such as for production, unit transfer or mobile equipment or furniture. They may hold a bearing in place or clip fabric to a frame. They are ideal retention devices across a very flexible area of applications and locations.

By their nature wire forms tend to be custom – although there are a number of standard formats such as J hooks, U clips and so on, even those tend to be produced on demand because they call for non-standard leg lengths for example. Today the technology of production is of course digital and extremely quick to output huge quantities, so little stock is generally required other than for world-wide delivery in support of very large manufacturing runs.

The cost of creating wire form prototypes has considerably decreased thanks to advances in CNC manufacturing technology so that Lee Spring’s engineering team can work with customers to ensure that a particular wire form part meets critical spatial requirements and can produce prototypes as part of their concurrent design process. Frequently, prototypes can be changed and produced in minutes, saving time and costly design errors, allowing the “proofing” process to be essentially uninterrupted so ensuring the final product achieves a timely market availability.

At Lee Spring, spring clips have been found to invariably require the custom touch which their expert sales team are extremely experienced in providing.

Further information on Lee Spring products can be found on their website – www.leespring.co.uk or by following them on Twitter – https://twitter.com/leespringuk.