An increasing number of design parameters and boundary conditions constitute a key challenge in the optimization of electronic circuits. Computer based automated algorithms offer a strong alternative to traditional empirical methods or extensive mathematical efforts.

The ever increasing requirements power electronic systems have to meet are leading to circuits and controllers becoming increasingly complex. As a result, engineers are faced with a challenging array of design parameters and criteria. Frequently used methods such as empirical parameter optimization based on experimentally or mathematically determined initial values are uneconomical when a certain degree of complexity has been reached, as in the case of cascaded controllers. The use of computerbased optimization algorithms within an automated optimization process on the basis of suitable strategies from systems theory rather than heuristic methods represents an excellent alternative. The “Optimization Workbench” (OWB) framework was developed to run such algorithms within a circuit simulation. It offers a rich and intuitive front end with a number of generic functions as well as a simulator interface, project configuration tools, and extensive postprocessing capabilities. Additional algorithms can easily be added as external plugins. Initially, optimization using a genetic algorithm (GA), Monte Carlo (MC) analysis, and parameter sweep/permutation (PSP) are available. While MC merely involves a random search (often referred to as “analysis of statistical experiments”) and PSP a simple scan, GA is a highly sophisticated, multi criteria optimization method. Based on the natural evolutionary process, it applies genetics to a wide range of complex optimization problems where target functions may be irregular and multimodal and information about the extreme values is difficult to find by other means.There are, of course, a number of other extremely powerful methods for multi-criteria/multi-target optimization. Yet genetic algorithms are so fascinating from an engineer’s point of view because these methods combine power and efficiency with user friendliness, because they are effectively “natural.”The GA implemented in this study is not intended to be a detailed model of biological evolution, but rather to improve the dynamics and power quality of, for example, power electronic devices by iteratively applying basic evolutionary principles such as selection, recombination, and mutation to the parameter vectors of a simulation model. Beginning with a group of random parameter vectors within a defined search space, recombination and mutation are used to form parameter vectors derived from them. Through the selection process, the suitable candidates for the next iteration are selected on the basis of their individual fitness, which in turn was determined by the simulation.

Highly flexible with minimal programming effort

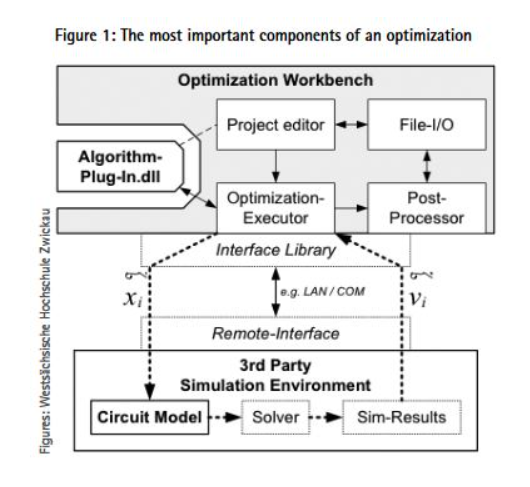

In addition to the algorithm itself, the process of performing computerbased optimization requires a variety of genetic components. The structure of the OWB according to these requirements is shown in Figure 1.

The OWB’s project editor (Fig. 2a) is used to create a configuration for planned optimization runs. Based on the properties of the selected optimization algorithm, various dialog boxes are presented on the front end in addition to generics such as simulator configuration and report settings. During the configuration stage, user actions, algorithmspecific dialog boxes, and parameter settings are hosted from the editor environment and can be controlled by the selected plugin, if required. This approach offers a high degree of flexibility with minimal programming effort.Once an optimization run is started, the Optimization Executor prepares the simulator and postprocessor before passing control to the algorithm. The plugin now begins generating parameter sets and captures their results via simulation with a single synchronous method call. The collected results can be transferred to the postprocessor (Figure 2b) by calling another method. The postprocessor uses an internal automated function to dynamically adjust and update its layout based on the reported results. After and even during an optimization run, the user can examine the archived results in the postprocessor module. It offers three main components: a template based parameter report, a results table containing the reported values from the algorithm, and a highly configurable 2D result diagram synchronized with the contents of the table for the purpose of graphical analysis. In addition, the user benefits from various options for exporting the archived data to other applications for deeper analysis.At the present time, three important plugins (GA, MC, PSP) are implemented by default. GA, which is based on the open JGAP library, offers a rich set of tuning parameters and is therefore suitable for a wide range of optimization tasks. The MC analysis can be used for exploratory optimization as well as to pre-optimize parameter constraints for more sophisticated algorithms like GA. The PSP plugin can be used to sample system properties within an n-dimensional search space by simulating all permutations of the parameter specific target value vectors.An important feature of the OWB design concept is the ability to easily define additional plugins. Since the OWB performs the genetic tasks itself, a well documented and simplified interface design allows the user to focus on implementing the optimization algorithms. Should the user have expanded requirements, the interface still makes it possible to influence or interact with most of the OWB’s automated functions.With support for all .NET languages such as C#, VB.net, and VC++, the well structured GUI, and the ability to use the freely available IDE from Microsoft Visual Studio, implementing and debugging new plugins is easy and efficient. In this way, the OWB can be adapted to any optimization challenge that can be solved with computer based methods.On a fundamental level, OWB was designed to provide an intuitive and efficient user interface with extensive error reporting in case of incorrect user action. In addition, due to the sometimes long optimization runtimes, the application was written to be stable and highly fault tolerant to avoid sudden crashes and data loss.

Conclusion

The Optimization Workbench (OWB) presented in this article has proven to be stable and reliable in all of our numerous optimization runs. Designed as a convenient addon for existing simulation environments, it enables computer based optimization with minimal integration effort. The system makes it possible to accelerate complex design processes and optimally exploit technical system reserves.Thanks to the optimization capabilities already implemented in the OWB, but also because of the equally available plugins for the design of controllers and power electronics, the software is extremely versatile. With its intuitive user interface, it represents a convenient tool to assist development engineers in this domain.Consequently, the tool is already structured to be extended for operation in simulation cluster environments in order to reduce the required optimization time by running simulations in parallel. To optimize grid models, an interface to simulators such as ATP and Cerberus is currently being evaluated in order to meet future requirements resulting from smart grid developments.