Some of the largest machinery in the world depends on the smooth operation of tiny ball and roller bearings. In order to detect abnormalities in bearings that can hamper machine performance, 100% inspection is required by state-of-the-art machine vision systems. Ideally, this inspection would be fast, automatic, and contactless to avoid any damage to the bearings.

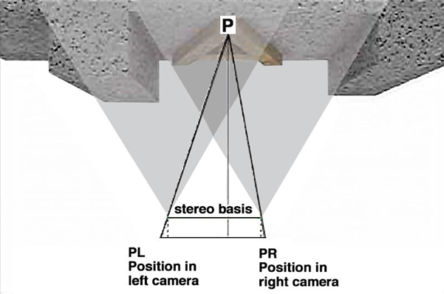

Active Inspection, a system integrator for image processing systems located in Grand Rapids, Michigan (USA), has developed just such a system based on the Chromasens 3DPIXA 3D stereo line scan camera and Chromasens Corona II LED illuminator. Engineers at Active Inspection customized a version of the company’s aiUltimate Max 3d inspection system so it can check virtually any type of ball or roller bearings by simple teach-in, and detect microscoptic defects to 3 μm.

“Analysis of all potential defects along with the large variety of roller, ball and sleeve bearings to be inspected at high speeds indicated that only a tailor-made inspection system could meet the requirements of this particular bearings manufacturer,” said Arun Dalmia, Managing Director of Active Inspection. “Both sides of the bearings would need to be inspected at up to 80 parts per minute. Defects included missing balls, rollers and needles, missing pins, incomplete imprints, and scratches, as well as dents, and flatness control. Press defects were of particular concern.”