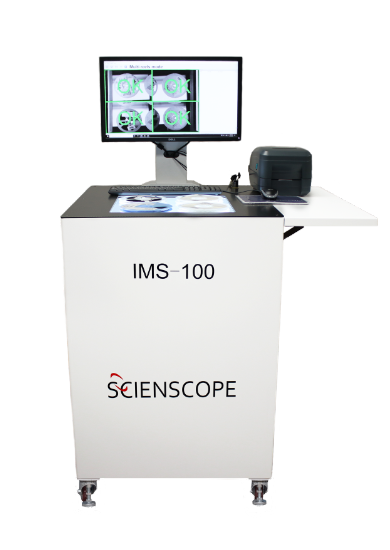

With the mounting supply chain pressure and difficulty in sourcing components causing havoc to production lines up and down the country, Altus Group, is adding further technology to its equipment portfolio to help achieve the smart manufacturing goal and increase component traceability. The latest addition is the innovative Scienscope Reel Smart Lite, a high-resolution goods in scanning table with integrated barcode camera system.

For component traceability and stock management processes to work effectively, it is important to ensure systems are in place to record and effectively monitor components that are available in the production facilities. The Reel Smart Lite system has been developed to help automate incoming processes offering immediate component traceability throughout production and make the relabeling process efficient and effective, therefore, reducing human error.

Joe Booth, Altus CEO said: “Many packed components are received which can include several labels including barcodes from manufacturers, distributors, forwarder’s barcode, and the customers’ barcode. This can make it difficult for the person scanning to pick the correct barcode to scan. Any incorrect reading can lead to an inventory and manufacturing process issues including line downtime. Scienscope Reel Smart Lite offers the solution to this problem by reading all data and providing one all-inclusive unique barcode label. This effective documentation of data ensures traceability is reliably implemented during production.

“Reel Smart Lite is designed to be compatible with endless vendor templates and so can be incorporated seamlessly into an automated production line or ERP to ensure it works with the Industry 4.0 ideal.”

Scienscope Reel Smart Lite offers complete control and reliability of part data thanks to its impressive and easy to use technology which helps to optimise cycle times.

The high-resolution barcode camera system has an image-based algorithm that reads and stores the information of four 7” reels simultaneously. As one reel is removed, a unique identification number label is automatically printed, archiving reliable data that can be easily and conveniently traced.

The system includes free MES and ERP integration, together with automatic data entry. The new label double-check mode and dual-sided label ensures all data is included and recorded with ease. Thanks to its Unique Identifier relabelling feature full traceability is assured.