Sophisticated automation control systems require precision position measurement, and this is especially true in industrial applications such as robotics, where the need for precise motion control requires highly accurate measurement. High precision, robustness, and other compelling benefits are possible with inductive encoding.

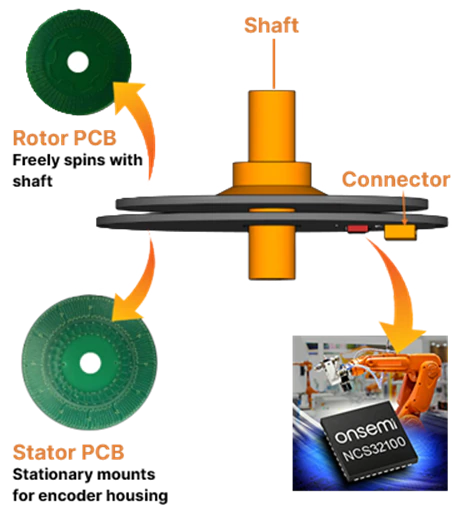

onsemi developed a new Industrial Rotary Position Sensor to combine high accuracy, high speed, and robustness—taking inductive position sensing to a new level and making it suitable for industrial applications. This innovative approach uses patented inductive sensor design techniques that enable it to deliver much higher accuracy than other inductive position sensors.

The new Dual Inductive architecture from onsemi is a versatile approach for various mechanical measurements. The primary use is for rotary position (and velocity) sensing, where the technology can deliver 20-bit resolution. A wide variety of sensor sizes are possible to address many different applications.

At rotational speeds of around 6,000 RPM, +/-50 arcsec accuracy can be achieved with a 38 mm sensor. The NCS32100 can operate all the way up to 100,000 RPM if the sensor is designed for it – albeit with reduced accuracy at higher speeds.

Inductive sensors are insensitive to almost all forms of contamination or interference, including liquids, dirt and dust, magnetic fields, EMI, and strong vibrations. With its low sensitivity to mechanical vibration, the NCS32100 can discriminate between rotor-to-stator translation and rotor-to-stator rotation. For example, it can distinguish between rotational movement (which is measured) and vibration in the x, y, or z axis (which can be rejected if desired).

The NCS32100 offers a level of integration that makes it a simple and easy-to-use solution. It contains an Arm® Cortex®-M0+ processor with Flash memory to store configuration settings. It comes with an integrated and fast self-calibration routine (to minimize production time) which allows it to compensate for PCB asymmetries. This calibration only requires that the rotor turns and completes in 2 seconds. It has an easy-to-use programming interface used with various sensors and PCBs with different designs, shapes, sizes, and form factors for maximum design flexibility.

This solution directly outputs position and velocity in a digital format, removing the need to derive this information from a raw analog signal. The NCS32100 can reduce the number of other components needed and the design time and risk. A solution based on NCS32100 could be done with 12 components, while a comparable 38 mm optical encoder requires over 100 components. Comparing these two solutions, a sensor based on the NCS32100 provides an order-of-magnitudereduction in the BOM.

Flexible mechanical specifications allow for achieving +/- 50 arcsec accuracy in real-world conditions. For example, a rotor-to-stator air gap of 0.1 mm to 0.5 mm is perfectly acceptable with the NCS32100 reference design, as is a rotor-to-stator tilt that does not exceed 0.5 degrees. The sensor can achieve different airgaps other than the 0.1 to 0.5 mm offered by the reference design, and 1 mm is a common typical airgap. In addition, no reference encoder is required for self-calibration; simply ensure that the rotor moves between 100 RPM and 1,000 RPM.

High levels of configurability enable use with a wide range of PCB sensor designs, allowing end users to configure and differentiate their solutions.

The front end of the NCS32100 features an automatic gain amplifier (AGC) and an integrated analog-to-digital converter (ADC). The integrated Arm® Cortex®-M0+ microcontroller includes non-volatile Flash memory (NVM) and a configurable interface for communication with the host processor.

A range of optional features is available to enhance the NCS32100 further, including latency extrapolation, low pass filtering (LPF), open coil detection, and auto-zeroing. Additionally, reference design and evaluation boards are available for designers to enable rapid evaluation and fast time-to-market.

Accurate position sensing is essential in many industrial applications with fast-moving machinery. The combination of accuracy, speed, integration, ease of use, robustness, and insensitivity to almost contamination or interference make the NCS32100 a very beneficial solution.

The Industrial Rotary Position Sensor from onsemi provides the optimum solution for rotational sensing in industrial applications. Learn more about the NCS32100 and the new approach for inductive position sensing that enables a new breed of high-accuracy rotary position encoders.