www.mentor.com

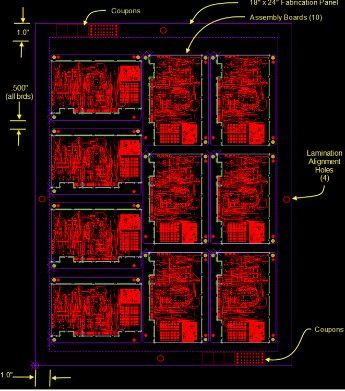

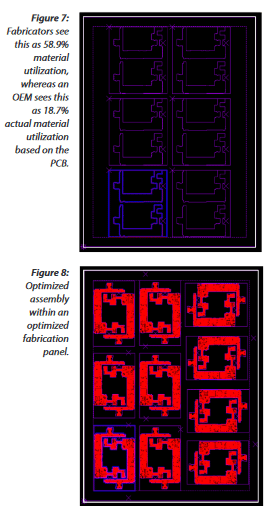

In reality, what the OEM cares about is the actual material area used for the PCBs, not the assembly panel, because that determines how many panels need to be built for the order. As illustrated in Figure 7, the fabricator will report this material utilization at 58.9%, but because of the shape of this PCB, the actual material utilization is only 18.7%.

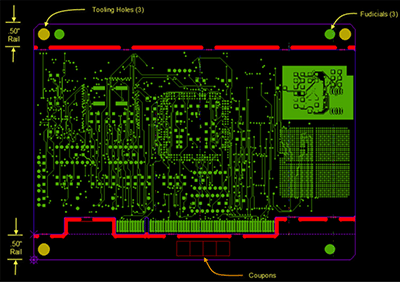

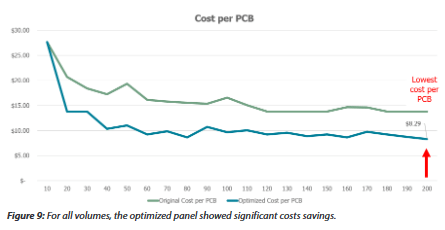

At Mentor, we studied four different designs, each with their own definition of production volume, to measure the potential material savings to an OEM. PCB 1 is a rigid PCB built in lot sizes of up to 2,000. Figure 8 illustrates that before panel optimization, the OEM was getting 18.7% material utilization on an 18 x 24 in. fabrication panel with two PCBs per array and six arrays per panel.

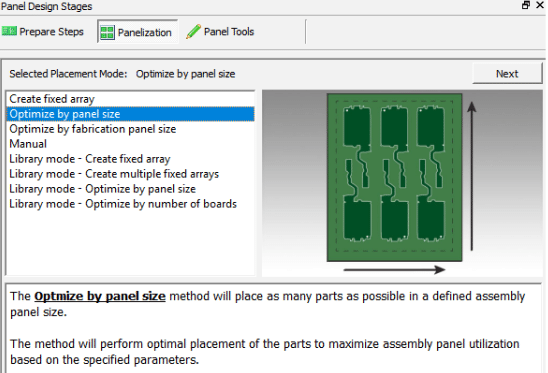

When the OEM optimized their assembly panel, they found they could get 31.5% material utilization, yielding 10 arrays of 2 PCBs per fabrication panel. The Valor NPI panel design and optimization software automatically nested circuits into a tighter assembly panel in spite of its non-standard shape.

We then applied the results to a simple costing spreadsheet that considered:

• Number of PCBs ordered.

• Fabrication panel square area.

• Fabrication panel cost per square inch.

• Fabrication panel overage needed (to accommodate scrap).

The fabrication panel overage is a variable because lower percentages are required with higher volume. All other variables were considered to be constant between the two scenarios.

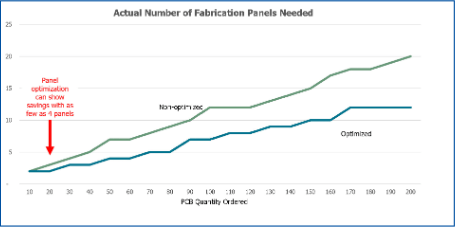

For the first example, we calculated the costs before and after panel optimization for order sizes between 100 and 2,000, in increments of 100.

As shown in Figure 9, in all volumes the optimized panel showed significant costs savings. Furthermore, we identified the order size that yielded the lowest cost per PCB. Which begs the question, would you change your order size if you knew where the lowest possible cost per PCB is?

Figure 10 shows the actual number of fabrication panels needed, non-optimized and optimized. While it might initially be surprising that these lines are not entirely straight, they reflect the combination of variables previously stated. What may be even more surprising is that panel optimization can show cost savings in as few as four panels for this design.Lastly, over a test sample of four PCBs, again each with their own production volume, there are impressive savings across the board, even when only a small number of PCBs are designed

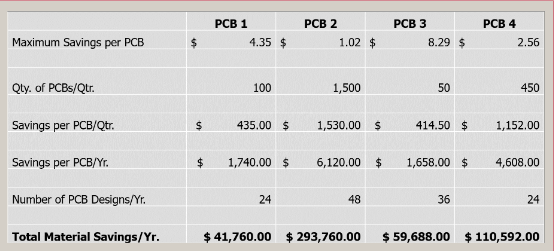

each year (Table 1).

Lastly, over a test sample of four PCBs, again each with their own production volume, there are impressive savings across the board, even when only a small number of PCBs are designed each year

(Table 1).

As an added bonus, when considering the labor costs involved to define, create, and communicate all the panelization instructions, a systematic panelization tool also can have meaningful labor savings.