Contributes to the Long-Term Design Quality of Displays in Industrial and Consumer Applications

Availability: Now

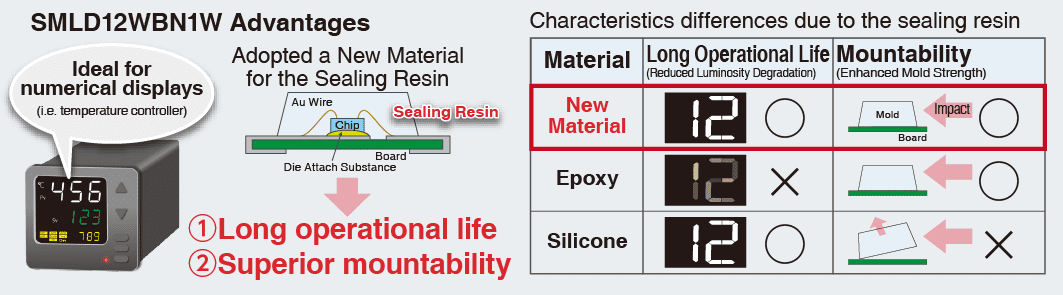

Key Features

1. Successfully maintained 100% luminous intensity during operational testing (25°C, IF=20mA, 1,000hrs)

Traditionally, Red and Green LEDs used in display panels of industrial equipment are less prone to cause yellowing of the resin due to light energy. Therefore, luminosity degradation has not been regarded as a problem. Epoxy resins with high mold hardness are commonly adopted for compact molded type LEDs. However, in the case of LEDs with a short wavelength (λD<527nm) such as White, the resin may turn yellow due to the energy of the light.

To address this issue, the SMLD12WBN1W utilizes a new material for the sealing resin that maintains 100% luminosity during operational testing (25C, IF=20mA, 1,000hrs). This results in approx. 20x longer life when compared to the residual luminosity shown under the same conditions by similar products available in the market.

2. 25x higher package strength than those using silicone resin

Although light intensity degradation can be improved by adopting silicone resin, the molding becomes easier to detach from the substrate. Measures to enhance mounting strength such as adding reflectors to compact LEDs cannot be used, and damage to the molding section remains a challenge.

The use of a new resin material improves the molding strength by 25x when compared to products using silicone resin even at high temperatures (Ta=150C). This minimizes defects during mounting on circuit boards, thus achieving superior mountability.

Lineups