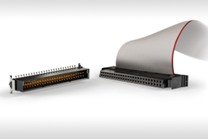

With the SMC (small multiple connector) family introduced in the late 1990s, ERNI was the first company in the world to develop a pure SMT connector system. In addition to SMT as the termination method, the aim was to reduce the DIN pitch from 2.54 mm to 1.27 mm and thus to advance miniaturization. More than two decades of continuous development have resulted in a comprehensive product family with female and male connectors (straight and angled), different heights and pin counts from 12 to 80. In the meantime, IDC female connectors, board-on-IDC connectors, male connectors in press-fit technology, board-to-board adapters and versions with integrated locking are also available as part of the SMC family.

SMC connectors can be found a million times over in applications such as industrial controls (PLC), power electronics such as inverters or battery management systems, remote I/O, frequency converters, controls for solar systems, and much more. The main reasons for the success and the wide range of applications are the high flexibility, the space-saving 1.27 mm pitch, the high contact reliability with ERNI’s proven dual-beam female contact and the high mating reliability thanks to polarization and lead-in chamfers – coupled with high manufacturing quality despite miniaturization.

Increasing device functionality/integration requires higher data rates, higher pin counts and smaller pitch dimensions – in other words, higher contact density. The comprehensive SMC portfolio combines these often-conflicting requirements and offers a wide range of solutions. The optimized contact design has an almost continuous impedance curve and, with the appropriate design, allows the secure transmission (differential) of data rates up to 3 Gbit/s. Many customers prefer SMT as a termination method and reflow soldering processes. When using connectors with a very small pitch, however, care must be taken to ensure reliable processing. To meet the industrial vibration and shock requirements, double-sided contacting (with vibration/shock tests up to 20 g/50 g) offers undisputed advantages. A full metal SMT bracket also absorbs high insertion and withdrawal forces.

With SMC connectors, leading and lagging contacts as well as partial assembly are possible. This means that the customer receives tailor-made products for their respective applications, with corresponding time and cost savings. The small pitch and the many designs enable miniaturized applications with optimum use of the installation space. The high contact reliability in combination with a high center and angular offset as well as protection against mismating (min. 2.5 mm) reduces failures in the field and thus saves time and costs.