Advanced Thermal Solutions is now providing DIY (do it yourself) cold plates for engineers to custom fit onto devices whose electronics need to be thermally managed for proper performance.

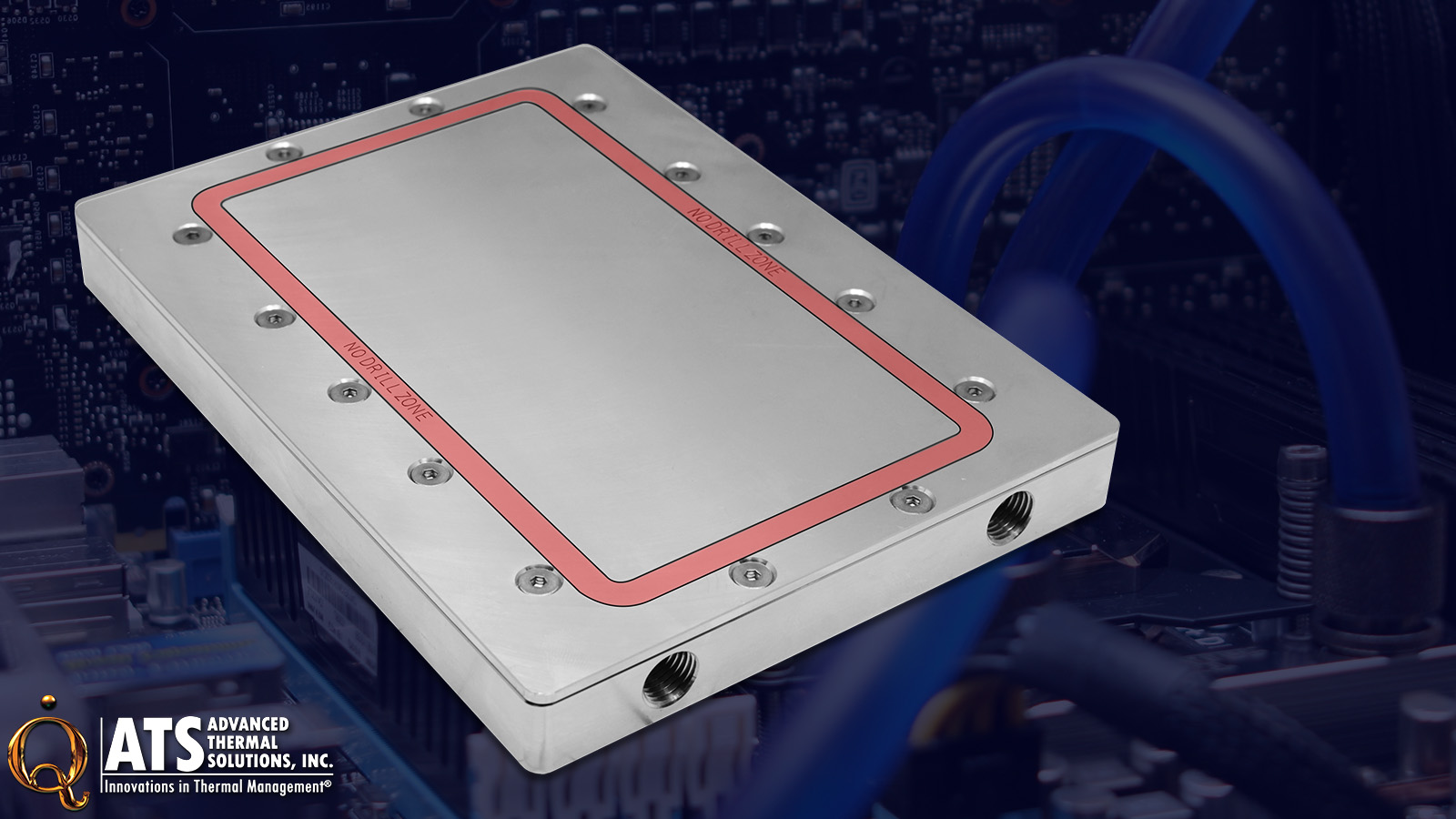

ATS DIY aluminum cold plates let engineers safely drill holes in mounting patterns that match the specific connection points of hot devices such as IGBTs, MOSFETs and other power electronics. Each cold plate includes an etched, no-drill zone to provide a visual exclusion guide.

Once an engineer has drilled holes and determined the optimum fit of the cold plate to their application, ATS can quickly manufacture and deliver the customized cold plate in volume.

Made in the US, ATS cold plates provide localized cooling by transferring heat from a hot device to a liquid that flows to a remote heat exchanger and dissipates into either the ambient or to another liquid in a secondary cooling system.

Lightweight and providing a uniform surface temperature, each cold plate’s internal, mini-channel fin structure enhances the surface area to maximize heat transfer with low pressure drop characteristics. ATS cold plates demonstrate more than 30% better thermal performance than other commercially available cold plates.

DIY cold plates have been used to develop cooling solutions for EV motorcycles, military vehicles, commercial aircraft, high power computing and fusion technology. They can bring high-performance liquid cooling to nearly any application where air cooling is insufficient.

More information about ATS DIY, do it yourself cold plates can be found at:

https://www.qats.com/Products/Wind-Tunnels/Closed-Loop-Wind-Tunnels/CLWT-067