The evolution of diode laser price and performance is rapidly opening new markets. In this article, the technology consulting firm IDTechEx Research demonstrate how advances in semiconductor laser technology enable novel applications in laser material processing and industrial manufacturing.

The discussion herein is based on the recently published report “Laser Diodes & Direct Diode Lasers 2019-2029: Technologies, Markets & Forecasts”. In this report, IDTechEx Research analyst Dr Nilushi Wijeyasinghe presents a comprehensive review of diode laser technologies, value chains, key player activities and global markets. Recent progress in material processing is highlighted using case studies, where she draws on her background in laser physics and semiconductor physics research to explain new technical concepts. Segmented ten-year market forecasts and technology roadmaps are based on the extensive analysis of primary and secondary data, combined with careful consideration of market drivers and restraints.

Evolution of Laser Diodes and Diode Bars

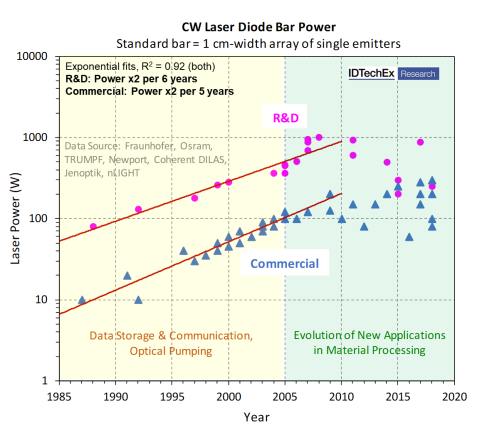

Technology advances have enabled lasers to progress from specialist technical instruments to a diverse range of markets. Laser diodes are the most widely available laser technology and are simple semiconductor devices. During the past three decades, the average power of laser diodes increased significantly, while their average price per watt decreased exponentially. Consequently, laser diodes are displacing some established laser and non-laser technologies, while enabling entirely novel optical technologies. Mature applications of laser diodes are data storage, data communication and the optical pumping of solid-state lasers. In contrast, material processing and optical sensing are examples of rapidly evolving market segments with many emerging applications.

The output power of a single laser diode can range from milliwatt to multi-watt levels. Power can be scaled up by combining single emitters into laser diode bars and stacks of bars and a standard bar has a width of 1 cm. For decades, there was strong competition between companies to increase the output power of diode bars, and an exponential growth trend was observed. While commercial diode bar products usually offer power less than 200 W per diode bar at 1 micron wavelength, research and development (R&D) divisions of laser manufacturers have demonstrated continuous wave (CW) average power exceeding 1 kW per bar. Increase in diode bar power enabled new applications in material processing, but some emerging applications demand the enhancement of laser parameters like wavelength stability and device lifetime. Therefore, competing on power is no longer the priority for companies in this market. The ongoing evolution of diode laser technology includes the improvement of infrared beam quality for precision engineering and the development of novel visible light lasers for metal processing.