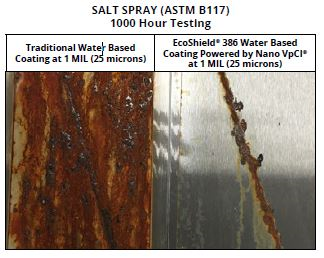

Cortec® Corporation is a frontrunner in the development of environmentally responsible corrosion solutions, including its line of water-based VpCI® micro-corrosion inhibiting coatings that achieve competitive results compared to traditional coatings technologies. Cortec’s water-based varieties minimize worker exposure to solvent fumes and typically reduce the amount of VOCs released to the atmosphere. Among its top-performing water-based DTM (direct to metal) permanent coatings is EcoShield® 386, which has been able to provide outstanding corrosion protection in salt spray chamber testing. Cortec® has recently expanded this unique portfolio of water-based anti-corrosion coatings by developing a new fast-dry version called EcoShield® 386 FD.

EcoShield® 386 FD combines the worker and environmental advantages of a water-based coating with the outstanding performance of EcoShield® 386 micro corrosion inhibiting technology in a topcoat that will force-dry in five to 10 minutes. This is ideal for manufacturers of pipes, tubes, and other metal components without enough time to cool and dry the coated parts before continuing the production process. The faster drying time of EcoShield® 386 FD makes it easier to handle components that need to be processed and stacked or packed right away, reducing or eliminating the problem of hot coated parts sticking to each other only to be pulled apart and cause coating failure and corrosion later.

EcoShield® 386 FD is a water-based acrylic one coat system (topcoat) that can be applied DTM at 1.5-3.0 mils (37.5-75 μm) DFT (dry film thickness) to provide protection in harsh, outdoor, unsheltered applications. It contains 0.6 pounds of VOCs per gallon (72 g/L) and is an excellent alternative to solvent-based and zinc-rich paints. Even though water-based, EcoShield® 386 FD provides outstanding corrosion protection. It relies on a complex mixture of non-hazardous “nano” sized corrosion inhibitors to provide a more continuous layer of corrosion protection in micro cavities where traditional inhibitors may leave gaps due to their larger relative particle size. EcoShield® 386 FD can be applied clear or matched to most custom colors for minimal change in surface appearance.

Corrosion protection is critical for newly manufactured metals headed for harsh, outdoor, or unsheltered conditions. Manufacturers who need to apply an inconspicuous protective coating to items such as new piping, tubing, refrigerator coils, or even painted equipment will find EcoShield® 386 FD an excellent option to incorporate into their production process. Workers are benefited, new products are protected, and manufacturers do not have to wait for coated parts to cool.