VJ Electronix, Inc., the leader in rework technologies and global provider of advanced X-ray inspection and component counting systems, today announced plans to exhibit at the Del Mar Electronics Show, taking place April 23-24, 2025 at the Del Mar Fairgrounds in San Diego, CA. At Booth 413, VJ Electronix team will discuss the Summit family of automated and semi-automated Rework Systems, XQuik III Component Counters, and Apogee X-ray Inspection Systems, each designed to enhance precision, automation, and efficiency in electronics manufacturing.

Summit 2200i: Precision and Automation Unleashed

The Summit 2200i is a state-of-the-art, fully automatic rework system designed for medium to large-sized Surface Mount Device (SMD) assemblies. With the capability to handle boards up to 22” x 30” and components as small as 01005, the Summit 2200i sets a new industry standard in precision and automation. Key features include:

- Automatic alignment for components up to 100mm square, reducing operator intervention.

- Advanced thermal control for optimal soldering and rework precision.

- Enhanced process automation, minimizing manual handling and improving repeatability.

Also highlighted will be the Summit LXi/LT120 systems with capability of handling boards up to 650 x 1200 mm and components up to 120 mm.

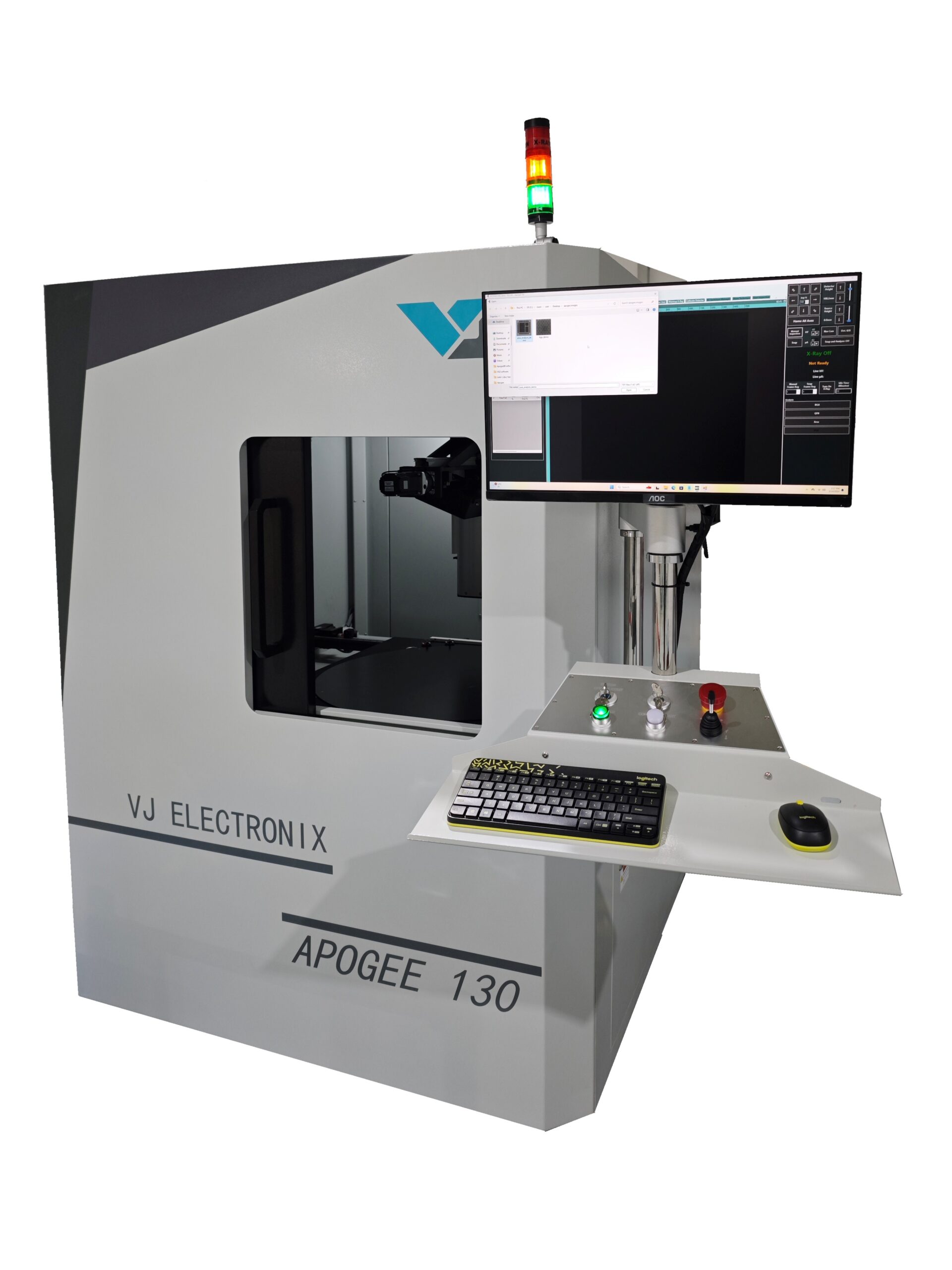

Apogee 130: High-Resolution X-ray Inspection at an Affordable Price

The Apogee 90 and 130 delivers superior 2D & 2.5D X-ray imaging for a variety of applications, including PCBs, electrical components, medical devices, counterfeit component screening, and wire harness inspections. Key advantages include:

- High-clarity imaging with advanced defect detection for BGA, QFN, PTH, and solder voids.

- New Vi5 software integration, featuring real-time visualization, auto contrast, and advanced defect enhancement tools.

- User-friendly GUI for intuitive operation, reducing training time and increasing efficiency.

With maintenance-free X-ray components and a long service life, Apogee systems provide high-resolution, automated X-ray inspection at a cost-effective price point, making it a valuable addition to production and quality control environments.

XQuik III: The Smart Factory Component Counter

The XQuik III is a fast, accurate, and intelligent X-ray counting system engineered for modern electronics manufacturing. With a cycle time of less than 10 seconds, the XQuik III eliminates the inefficiencies of slow, manual inventory counting—an issue made even more critical amid ongoing component shortages that can lead to line-down situations.

Key benefits of the XQuik III include:

- Industry-leading count accuracy of over 99.8% using AI-driven automatic component recognition.

- Fast cycle times: Counts both a large reel and four small reels in under 10 seconds, including automatic barcode scanning.

- Push-to-start operator experience for simple, efficient use.

- Flexible MES interface for seamless communication with any inventory control system.

- Pass-through automation capability for smart factory integration.

VJ Electronix invites attendees to visit Booth 413 to explore how these cutting-edge solutions can enhance precision, efficiency, and automation in electronics manufacturing. For more information or to schedule a demo, visit www.vjelectronix.com.